A Team D3 Client Success Story with Britten, Inc using Autodesk Software Solutions

The Customer

Britten, Inc. is a veteran-owned creative production house, dedicated to delivering innovative signage, displays, and event branding solutions. For 35+ years, Britten has used state-of-the-art design, printing, fabrication, and manufacturing capabilities to produce high-impact campaigns.

The Customer’s Challenge

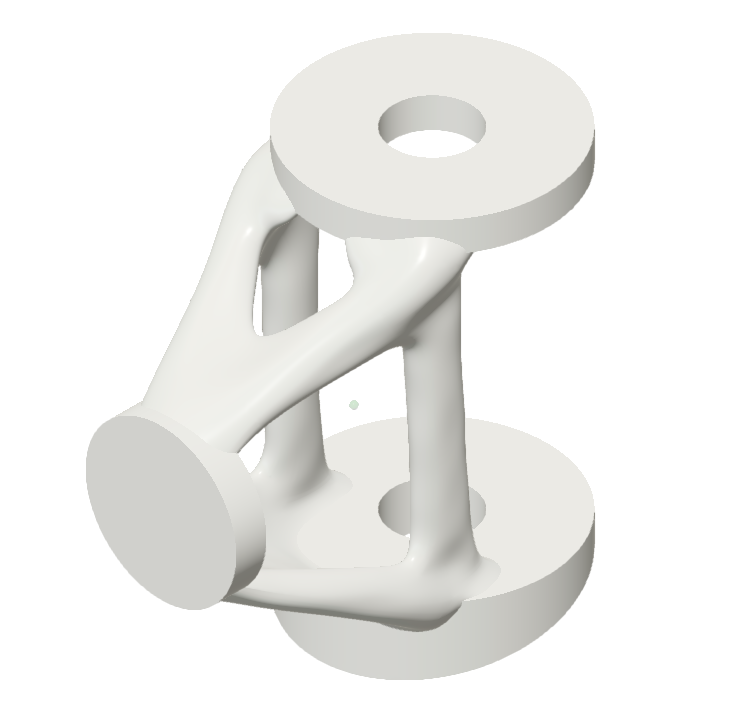

The challenge Britten faced was to redesign a “tried and true” part, that has been sold in the marketplace for years, to secure “intellectual property” for the redesigned part through a registered patent. The design had to be unique enough for Britten to apply for and receive a patent.

The Project Goals

Britten’s project goals included, but were not limited to:

- Part weight reduction.

- A new contemporary design using unconventional materials other than cast metal, which could exceed current and potentially heightened performance standards.

- The reduction of time and cost of the design development phase.

- A desire to reduce prototype cost and iterations through the application of procedures that would allow them to insert critical design standards that would drive digital physical functionality and advanced materials analysis performed early in the concept and design phase.

The Solution

The Autodesk Fusion/Generative Design Extension solution was prescribed by Team D3 and adopted by Britten, Inc. Generative Design, provided in Autodesk Fusion, situates critical design constraints, often overlooked until late in a product’s lifecycle, at the forefront of the design process. Users are prompted to define material types, manufacturing considerations, performance criteria, and part durability requirements in an early “stage gate” of the design process. All criteria are then used concurrently in synthesizing a wide array of probable solutions with cloud-based solving. The Generative Design method enables the design team to consistently pick the best possible solution thus abbreviating the lifecycle of the product and ensuring that the final creation is dependable in functionality, durability, and longevity. As an added benefit to the Autodesk Fusion/Generative Design solution, Britten chose to use Autodesk Vault to manage its engineering revision control workflow.

The Business Outcome

With Autodesk Fusion and the Generative Design Extension, Britten was able to significantly reduce the time necessary to find and confirm the best possible design solution outcome early in the design product lifecycle. The Generative Design tool has yielded substantial savings in time and money spent because it can quickly create and analyze digital 3D prototypes during the design process without the need to produce multiple iterations of physical prototypes.

By implementing Generative Design into their design workflow, Britten has improved the product’s performance while reducing resource consumption. With the time and cost savings they have experienced, it is expected that their manufacturing throughput will yield a marked increase while also growing their market share once they gain their patent.

Conclusion

Britten has discovered in the amalgamation of Autodesk Fusion and Generative Design, an innovative solution that gives them design and fabrication technology that positions them as “best in class” in their industry. When added to Autodesk Vault, Autodesk Inventor, Autodesk Revit, and Autodesk 3ds Max, they are equipped with a formidable collection of digital design and manufacturing resources along with rapid cloud-based computing. With the Autodesk Fusion/Generative Design creation tool in place and fully adopted into their normal design process, Britten expects to discover other related applications and new workflows as the future unfolds.

“The ‘Autodesk Fusion/Generative Design’ function has essentially added a skillset to our team that we’d otherwise have a hard time finding in an individual. The ability to quickly iterate designs, provide input feedback, and iterate again and again, is something I’ve found hard to quantify in terms of labor and time savings. It has forced us to think outside historical design constraints and reach novel solutions to problems that have lingered for years. It’s a very powerful tool with a manageable learning curve and importantly at a cost that is highly accessible. We’re completely sold on its capabilities and thankful to be able to use it.”

-Nathan Bildeaux, Director of Engineering